Update for neje dk-8-kz software. There are several reasons for this dynamic: First, new technologies are emerging, as a result, the equipment is being improved and that, in turn, requires software changes. NEJE DK-8-KZ, DK-8 PRO-5, DK-6 PRO-5, JZ-5, JZ-5-T, DK-5 Pro-5 engraver comes with a 1GB micro SD card, the files on the SD card are including the USB-Serial driver, engraver software and few JPG photos as shown in figure below. The NEJE FKZ is very small focus. Jun 8, 2016 - The NEJE DK-8-KZ laser engraver is great for precision engraving on.

How-to’s and resources for upgrading the NEJE (also sold under the HICTOP brand, and others) desktop USB laser engraver to full GRBL compatibility by replacingthe electronics.

Last updated January, 2018.

Full grbl upgrade with Arduino CNC Shield

Videos

I have uploaded a video of the whole upgrade process at youtu.be/2rbzI-d-bOA.

A second video with specific focus on the wiring, and that covers use of aMOSFET to switch the laser, is also available at https://youtu.be/MuKYvifYnYs.

Links to resources

Software-only upgrade

Neje Dk-8-kz Software

If you are lucky enough to have a machine that can be upgraded without replacingthe board, you can follow these instructionsto flash a new version of grbl to it.

Hardware

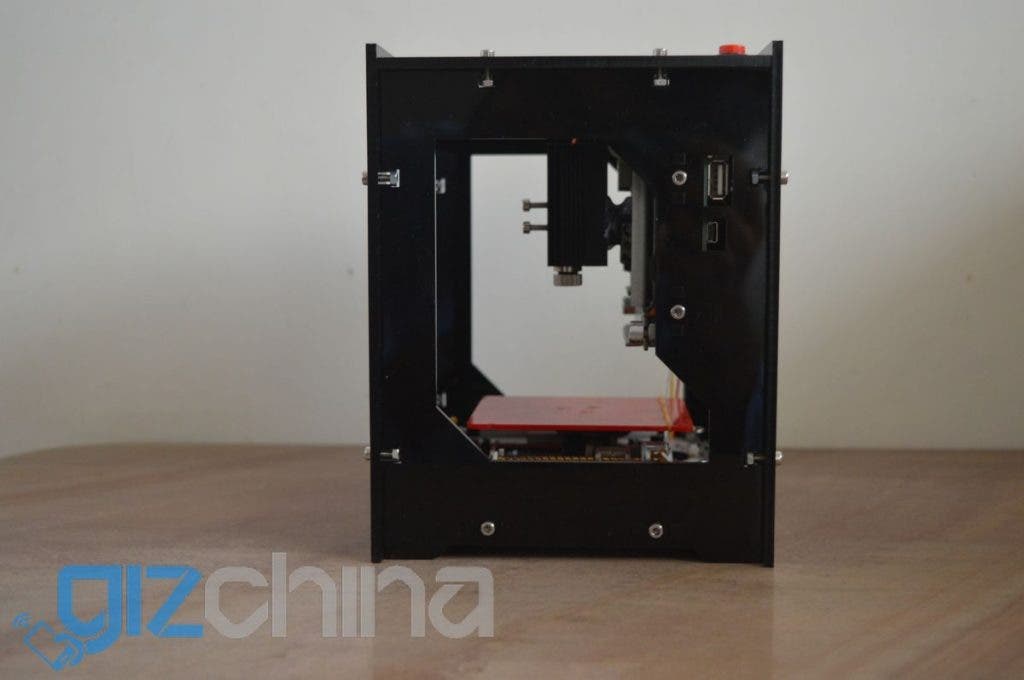

The engraver pictured above and in the video: KKmoon NEJE DK-8-KZ 1000mW

The Arduino shield used to control the steppers: Arduino CNC Shield.I think I mistakenly referred to this as “grblshield” in the video.

Arduino Uno, the board that connects to the shield above.

Laser focus adjustment ring.

IRF520 module, the board thatcontrols power to the 5V laser.

Software

Universal Gcode Sender -Used to send commands to the laser.

J Tech Photonics Laser Tool -Used to convert images to laser commands.

Wiring diagrams and schematics

Connecting PC power supply to Arduino and Shield

The CNC shield can accept any DC voltage from 12V to 36V. Because the steppermotors used here are very small, the 12V does not need to be high amperage;500ma or larger will probably be sufficient.

To power the upgrade, I used a power supply designed to run an internal PChard drive, although a full-size PC power supply would work.

The most important part of the power supply is that is can give 5V at severalamps to power the laser.

The CNC shield electronics can then be powered from 5V as well, but I choseto power them from the 12V rail of the power supply. If you choose to do that,you will want to adjust the current-limit on the drivers to avoid damaging thestepper motors. Details of how to do this are in the video.

Connecting stepper motors to the shield

The connector for the stepper motors are between the “drivers” (the red square circuit boards in this image.

With the white wire facing up, match the 4-pin connector on the cable to the4-pin connector on the board for both the X- and Y-axis.

Connecting laser to power supply and CNC shield

The SPNEN (SPiNdle ENable) pin on the shield cannot power the laser itself, soI use a circuit with a transistor to power the laser from the power supply, butstill allow it to be turned on and off by the CNC shield.

First, you will connect the positive wire of the laser (coloured red on mine) tothe 5V power line from your power supply. It MUST be 5V, any more will damagethe laser!

We will switch the laser on and off by connecting or disconnecting thenegative/ground wire. This technique is known as “low-side switching”.

Here are two ways to do it, though there are probably other ways too. Irecommend using a MOSFET over a TIP120. But if you only have a TIP120 it willstill work though your laser power may suffer.

MOSFET circuit

An efficient way to switch the laser on and off is to use an N-Channel PowerMOSFET. Currently I am using an IRF520 module like this one, but this is not designed for logic-level switching so if you have the option I wouldrecommend using a logic-level MOSFET instead.

But, regardless of the voltage, if you want to solder one yourself then thecircuit will look something like this:

This will switch the laser on and off with a minimum of voltage loss.

If you use the same IRF520 module that I did, here is how the wires areconnected:

TIP120 circuit

Before using the MOSFET, I was using a TIP120 Darlington transistor. This worksbut it is a poor choice because the voltage drop on a TIP120 can be as much as2V in some cases. If we were switching 48V then that wouldn’t be a problem butfor a 5V laser, losing even 1V is going to severely impact laser power.

Here is the TIP120 switching circuit I used before:

The transistor I used is a TIP120 “Darlington” transistor. It is a very common“power transistor” that you can find at any electronics shop (Radio Shack,Fry’s, etc) and everywhere online. You can use any similar NPN-type powertransistor (such as the TIP31, etc) as long as it can handle the current. Astandard 2N3904 transistor can’t handle it, and while a 2N2222 may be able tohandle it for lower-powered lasers, I would still recommend using a TIP-series transistor because they are still very inexpensive.

Note: I should really upgrade the above circuit to use a MOSFET insteadof a power transistor. It shouldn’t be that hard adapt it usingthe example from this page. It may alsolet us use PWM to control the intensity of the laser.

Orientation

The origin (X/Y at 0) coordinates should be at the lower-left of the of thestage. “Lower” here means nearest to front. Make sure moving each axisnegatively will move toward that point, and moving each axis positively willmove away from that point.

configuring grbl to work in positive space

For J Tech Photonics Laser Tool (in Inkscape), make sure to set the machinecoordinates system to operate in positive space. You will do that byuncommenting the following line in config.h before you upload the grblcode to the Arduino:

grbl 1.1 settings for Arduino CNC Shield upgrade

Reset default work area

You will probably need to reset the default “work area”. Do that with thesetwo commands:

UPC:798220796796This laser engraving machine features the function of print carving and more practical than normal engraving machine. This mini laser engraving machine with high precision and high stability is great for DIY engraving. It supports offline operation, convenient than normal engraving machine.

Features:

This laser engraving machine features the function of print carving and more practical than normal engraving machine.

High precision and high stability: with 108 screws and alloy structure make it strong.

Unique frame and weak light automatic positioning: frame positioning makes the image positioning easier.

Offline operation: this machine supports operating without computer, only need to prestore a picture and connect the two usb ports to charger or power bank(not included); one button to operate.

Professional power IC and radiator, carving time will last much longer and carving performance will be more stable than other laser.

Truly 1000mW blue laser head, high speed and support more types of materials.

Items can be carved including: mahogany, bamboo, paper cards, ivory, leather, flammable plastic, PCBA, etc.

Come with a pair of protective glasses to protect your eyes from getting hurt by laser.

Wide application: can be used for print, hand tools and industrial processing.

High resolution printing: 512*512.

IMPORTANT NOTE:

1.Because the software adds automatic connection function, need the operating system registry, this function may be mistaken for a virus by antivirus software, the software is developed by our company, does not carry the virus. Don't worry! If it is mistaken for the virus, please exit antivirus software before operating the machine. The probability of 5%. We hope for your understanding. If the software in TF card is deleted by antivirus software, you can download the new software from trusfer.com.

2.It can not engrave metal, acrylic and any other retardant material.

Specifications:

Material: Acrylic + Aluminum + Stainless Steel

Main Color: Black

Laser Power: 1000mW

Laser Wave Length: 405nm

Laser Wave Length: 405nmImage Format: jpg

Image Size: 512 * 512 pixels

Image Engraving Pattern: Bitmap Engraving

Support System: Win7 / Win8 / XP / Win10

Supply Voltage: 4.2-5.5V

Supply Current: 1A

Work Area: 38 * 38mm

Item Size: 16 * 14.5 * 19cm / 6.30 * 5.71 * 7.48in

Item Weight: 976g / 34.43oz

Package Size: 30 * 20.5 * 21cm / 11.81 * 8.07 * 8.27in

Package Weight: 1360g / 47.97oz

Package List:

1 * Engraving Machine

1 * Protective Glasses

1 * Protective Glasses2 * USB Cables

1 * Wrench